Our professional team will support you to go further!

Get a Quote. Ask a Question. We respond within 10 to 15 minutes during business hours.

capsule supplement manufacturer

Are you seeking a high-capacity, top-quality, fully certified capsule supplement manufacturer? Gensei consistently excels as the leading private label capsule manufacturer, delivering premium capsules on schedule and within budget. No matter the formulation, capsule type, or packaging you require, we’re here to support you.

Customization is essential. You can select the exact product to distinguish your brand from competitors. Size, appearance, formulation, or flavor—we’ll collaborate with you to bring your product to market, providing guidance every step of the way.

what is capsule supplement manufacturing?

Capsule supplement manufacturing is the process of producing dietary supplements in capsule form, typically for health and wellness purposes. It involves formulating, encapsulating, and packaging active ingredients—such as vitamins, minerals, herbs, or other bioactive compounds—into gelatin or vegetarian capsules for easy consumption.

The process includes:

- Formulation: Blending precise amounts of ingredients to meet specific health claims or nutritional goals.

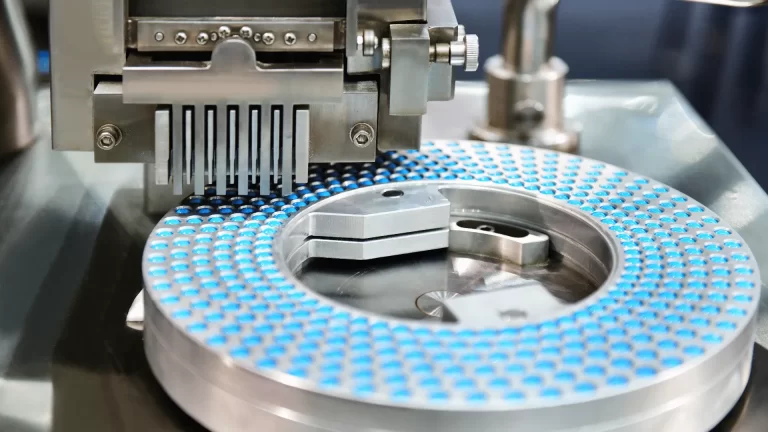

- Encapsulation: Filling capsules with the formulated powder or liquid using specialized machines.

- Quality Control: Testing for purity, potency, and safety to comply with regulatory standards (e.g., FDA, GMP).

- Packaging: Bottling, labeling, and preparing products for distribution, often customized for private labels.

Manufacturers like Gensei, as mentioned earlier, specialize in creating high-quality capsules tailored to client specifications, offering flexibility in formulation, capsule type, and branding for businesses aiming to market their own supplement lines.

Features of working with capsule supplement manufacturer:

Working with a capsule supplement manufacturer offers several key features and benefits, particularly for businesses looking to develop and market their own dietary supplement products. Based on the context of high-quality manufacturers like Gensei and general industry practices, here are the primary features:

- Custom Formulation:

- Manufacturers collaborate with clients to create tailored supplement formulas, combining specific ingredients (e.g., vitamins, minerals, herbs, or botanicals) to meet health goals, target markets, or regulatory requirements.

- Options for unique blends, potencies, or specialized ingredients to differentiate your brand.

- Flexible Capsule Options:

- Choice of capsule types, including gelatin, vegetarian, or vegan capsules, to cater to diverse consumer preferences.

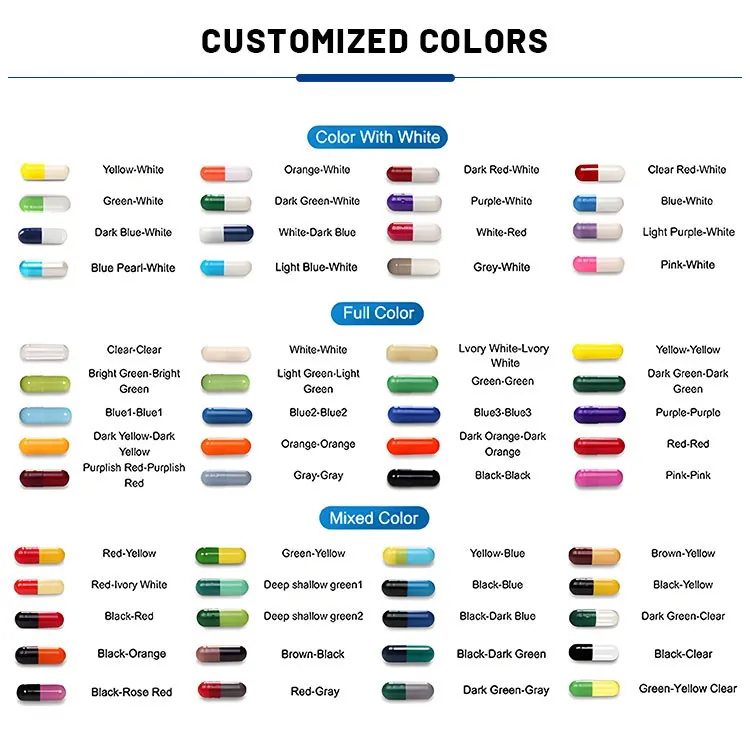

- Customization of capsule size, color, and appearance for brand alignment.

- Private Labeling and Branding:

- Manufacturers provide private label services, allowing businesses to market products under their own brand name and logo.

- Support for custom packaging designs, including bottles, blisters, or pouches, with professional labeling that complies with regulations.

- High-Quality Production Standards:

- Adherence to strict quality control and regulatory standards, such as Good Manufacturing Practices (GMP) and certifications (e.g., FDA, NSF, or USDA Organic).

- Rigorous testing for purity, potency, safety, and consistency to ensure consumer trust and compliance.

- Scalable Production Capacity:

- Ability to handle both small and large production runs, accommodating startups or established brands.

- High-capacity manufacturing ensures timely delivery, even for bulk orders.

- End-to-End Support:

- Guidance through the entire process, from concept and formulation to production and market launch.

- Assistance with regulatory compliance, ingredient sourcing, and product development to streamline the process.

- Cost Efficiency and Budget Control:

- Transparent pricing and production processes to keep projects within budget.

- Economies of scale for larger orders, reducing per-unit costs.

- Fast Turnaround Times:

- Efficient production timelines to meet market demands and launch schedules.

- Reliable delivery schedules to ensure products reach clients on time.

- Flavor and Delivery Customization:

- Options to enhance consumer experience, such as flavored capsules or specialized coatings for easier swallowing.

- Development of innovative delivery systems, like time-release or enteric-coated capsules.

- Market Expertise and Innovation:

- Access to industry knowledge and trends, helping clients create competitive, consumer-driven products.

- Support for incorporating trending ingredients or formulations, such as adaptogens, probiotics, or plant-based compounds.

By partnering with a reputable capsule supplement manufacturer, businesses gain access to expertise, infrastructure, and customization options that enable them to create high-quality, market-ready products efficiently and effectively. If you’d like, I can search for specific manufacturers or analyze posts on X for real-time insights into working with such companies. Let me know!

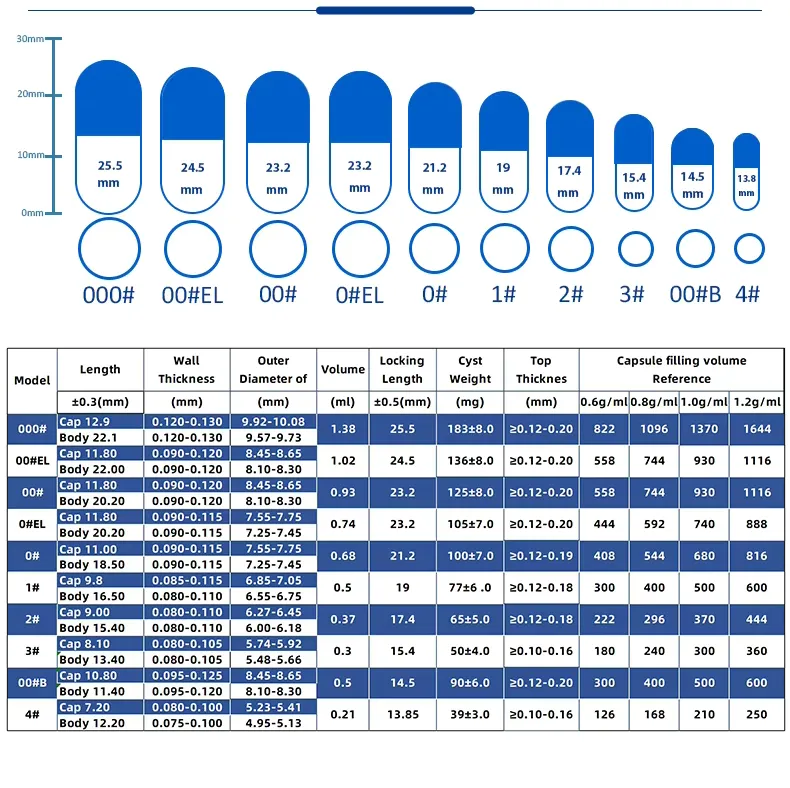

capsule size chart

A capsule size chart is a reference tool that outlines the dimensions, capacities, and uses of various capsule sizes (e.g., 000, 00, 0, 1, 2). Sizes range from largest to smallest, with 000 holding about 1.37ml of powder and 4 holding around 0.21ml. The chart typically includes details like capsule length, diameter, and suitability for different dosage forms (e.g., powders, granules, or liquids), aiding manufacturers and consumers in selecting the appropriate capsule based on formulation needs and ease of consumption.

Types of Dietary Supplement Capsules

| Primary Type | Specific Variation | Key Characteristics | Typical Contents | Primary Use / Benefit |

|---|---|---|---|---|

| Hard Capsules | Hard Gelatin Capsule | Two-piece shell made from animal gelatin (bovine, porcine, piscine) and water. | Primarily powders, granules, pellets, small tablets. Can be liquid-filled with proper sealing. | Most common type; versatile for solid fills; cost-effective; easy to swallow. |

| Hard Vegetarian Capsule | Two-piece shell made from plant-based material (e.g., HPMC, Pullulan, Starch). | Primarily powders, granules, pellets, small tablets. Can be liquid-filled with proper sealing. | Alternative for vegetarians, vegans, or those with dietary/religious restrictions; can offer better moisture barrier (e.g., Pullulan). | |

| Enteric-Coated Hard Capsule | Hard capsule with a coating applied to the outside after filling. | Powders, granules, pellets. | Protects contents from stomach acid; protects stomach from contents; targets release in the intestine. | |

| Delayed-Release Hard Capsule | Shell material or coating designed to delay release of contents after ingestion. | Powders, granules, pellets, mini-tablets. | Protects acid-sensitive ingredients (like probiotics, enzymes); allows targeted release further down the digestive tract. | |

| Liquid-Filled Hard Capsule | Hard capsule sealed after being filled with non-aqueous liquids, semi-solids, or suspensions. | Oils, lipid-based solutions, suspensions. | Improved bioavailability for certain compounds; alternative to softgels for specific liquid fills; can combine liquid with solid particles. | |

| Soft Capsules (Softgels) | Gelatin Softgel | One-piece, hermetically sealed shell made from animal gelatin, water, plasticizer. | Primarily liquids, oils, semi-solids, suspensions. | Ideal for encapsulating oils and liquids; hermetically sealed for stability; easy to swallow; rapid release in stomach. |

| Vegetarian / Vegan Softgel | One-piece, hermetically sealed shell made from plant-based materials (e.g., HPMC, starch). | Primarily liquids, oils, semi-solids, suspensions. | Alternative to gelatin softgels for those avoiding animal products. | |

| Enteric-Coated Softgel | Softgel with a coating applied to the outside. | Primarily liquids, oils, semi-solids. | Protects acid-sensitive fills; prevents stomach irritation/aftertaste; targets intestinal release. | |

| Chewable Softgel | Softgel with a modified shell and often flavored fill, designed to be chewed. | Liquids, semi-solids (often flavored). | Easier administration for those with swallowing difficulty; provides a pleasant taste experience. | |

| Twist-Off Softgel | Softgel with a tab designed to be twisted or snipped off to release liquid fill. | Liquids, oils. | Allows for precise dispensing of liquids; suitable for pediatric, veterinary, or topical use. |

How Does capsule supplement manufacturing Work?

Hard capsules are made in two separate halves: the body and the cap.

- Shell Creation: Stainless steel pins, mounted on plates, are dipped into a heated liquid solution (either gelatin or vegetarian material like HPMC or Pullulan).

- Drying: The pins are slowly rotated as they pass through drying ovens or kilns with controlled temperature and humidity. The liquid solution dries and hardens into a thin film on the pins, forming the capsule halves.

- Stripping and Trimming: Once dry, the capsule halves are automatically stripped off the pins and trimmed to the correct length. The cap and body are then joined together temporarily (pre-locked).

- Filling: The empty, pre-locked capsules are transported to a separate filling machine. This machine separates the cap from the body, fills the body with the powdered, granular, or sometimes liquid/semi-solid supplement material, and then rejoins the cap and body, locking them securely.

Choose the Right Package for Your Capsules

Bottles (Plastic or Glass)

- Description: The most traditional and widely used packaging format. Capsules are typically counted and filled into bottles, often with a desiccant to control moisture. Various plastic types are used (e.g., HDPE – high-density polyethylene, PET – polyethylene terephthalate), as well as glass.

- Pros:

- Excellent protection against physical damage.

- Good barrier properties against moisture and oxygen, especially with appropriate materials (HDPE) and liners.

- Offers ample space for labeling and branding.

- Familiar and convenient for multi-dose products.

- Child-resistant and tamper-evident closures are readily available.

- Cons:

- Can be bulky and heavy, impacting shipping costs.

- Transparency (like clear PET or glass) may require light-sensitive products to be bottled in opaque containers or stored in outer cartons.

- Plastic waste concerns (though many plastics are recyclable).

- Description: The most traditional and widely used packaging format. Capsules are typically counted and filled into bottles, often with a desiccant to control moisture. Various plastic types are used (e.g., HDPE – high-density polyethylene, PET – polyethylene terephthalate), as well as glass.

Blister Packs

- Description: Capsules are sealed individually within formed plastic cavities (often PVC or PVDC for barrier) with a lidding foil (usually aluminum).

- Pros:

- Excellent protection against moisture, oxygen, and light for each individual capsule.

- Provides unit-dose dispensing, ensuring freshness and preventing contamination of unused capsules.

- Clear visual inspection of the product (unless opaque foil/plastic is used).

- Compact and lightweight.

- Good tamper evidence.

- Suitable for samples or travel packs.

- Cons:

- Can be more expensive per capsule than bottles for large quantities.

- Less convenient for multi-dose daily regimens (requires popping out multiple capsules).

- Less space for detailed product information on the blister itself (usually requires a carton).

- Can be challenging for individuals with dexterity issues.

- Description: Capsules are sealed individually within formed plastic cavities (often PVC or PVDC for barrier) with a lidding foil (usually aluminum).

Pouches / Bags

- Description: Flexible packaging, typically stand-up pouches or sachets. Less common as primary packaging for individual capsules (except maybe single-serving sachets with a few capsules), but sometimes used for bulk quantities sold directly or to refill bottles. Multi-dose bags are sometimes used, but protection per capsule is limited once opened.

- Pros:

- Lightweight and often less bulky than bottles (especially lay-flat pouches).

- Can have good barrier properties depending on the film layers used.

- More surface area for branding.

- Often perceived as more modern or eco-friendly (though recyclability varies).

- Lightweight and often less bulky than bottles (especially lay-flat pouches).

- Cons:

- Capsules are less protected from physical damage than in bottles or blisters.

- Barrier protection for the entire contents is compromised once the seal is broken (unless using re-sealable zippers effectively).

- Less convenient for precise multi-dose dispensing compared to counting from a bottle.

- Not suitable for unit-dose presentation.

What Makes Us Unique As A capsule supplement manufacturer?

We design your specific capsule with your whole business in mind. With Gensei, you’ll get a trusted supplement manufacturing team who knows the industry and how to deliver the best product for your brand.

- Unparalleled Scale and Capacity: With one of the largest manufacturing footprints and supply chain networks in the industry, we possess the capacity to handle projects of virtually any size and complexity, ensuring reliability and scalability for your brand's growth.

- End-to-End Expertise: We offer a truly turnkey solution, guiding you from initial concept and custom formulation by our experienced R&D team, through rigorous sourcing, manufacturing, comprehensive quality testing, and flexible packaging options, all the way to getting your finished capsules ready for market.

- Specialization in Capsule Versatility: Beyond standard options, we excel in manufacturing a wide variety of capsule types and forms, including diverse hard capsule sizes (Gelatin & Vegetarian), and specialized softgels (various shapes, sizes, Gelatin & Vegetarian, Enteric-Coated, Chewable, etc.), allowing you to create highly specific and innovative products.

- Unwavering Commitment to Quality & Compliance: Our culture is built on quality. We maintain stringent cGMP standards and hold numerous certifications (like NSF, USDA Organic, etc.), backing every batch with thorough testing to ensure purity, potency, and compliance that you and your consumers can trust implicitly.

- Partnership-Driven Customer Service: We prioritize building long-term relationships over transactional interactions. Our dedicated team provides responsive, expert guidance, proactively solves challenges, and leverages our resources to streamline the entire process, acting as a true partner invested in your success.

- Capability for Complex Formulations: Our experienced formulators and advanced manufacturing capabilities enable us to successfully develop and produce complex capsule formulations, handling challenging ingredients or combinations that other manufacturers may not be equipped to manage.

- Competitive Value & Long-Term Focus: We offer competitive pricing strategies designed to foster lasting business relationships, providing value that supports your brand's profitability and ensures a consistent supply of high-quality capsules that consumers depend upon.

Frequently Asked Questions About capsule supplement manufacturing

Reputable manufacturers offer a wide range, including Hard Gelatin Capsules, Vegetarian/Vegan Hard Capsules (typically HPMC or Pullulan), Gelatin Softgels, and Vegetarian/Vegan Softgels. Many can also produce capsules with specific functionalities like Enteric-Coated (both hard and softgel), Delayed-Release (often using specific hard capsule shells or coatings), Chewable Softgels, and Twist-Off Softgels.

For Hard Capsules, the standard numerical sizes are available, most commonly #000, #00, #0, #1, #2, #3, #4, and #5. For Softgels, sizes are based on fill volume, typically measured in Minims or Cubic Centimeters (CC/mL), and come in various shapes (Oval, Oblong, Round, Tube, etc.). Manufacturers will have charts showing available sizes for both types.

Yes, manufacturers can produce capsule shells in a wide variety of custom colors and opacities (clear, translucent, opaque) using approved colorants. Printing services are also common, allowing you to print your brand logo, product name, or code directly onto the capsule shell using food-grade ink.

Hard capsules are primarily designed for dry fills including powders, granules, pellets, and mini-tablets. With specialized equipment and sealing methods, some hard capsules can also be filled with non-aqueous liquids or semi-solids.

Softgel capsules are specifically designed for liquid and semi-solid fills, such as oils, lipid-based solutions, suspensions, and pastes. They are not suitable for standard dry powders.

The exact weight of material a capsule can hold depends on the volume capacity of the capsule size and the density of your specific fill material. Manufacturers use charts and density calculations to determine how much of your unique formula will fit into a chosen capsule size. For softgels, capacity is typically defined by volume (Minims/CC) rather than weight due to the liquid fill.

Experienced manufacturers have technologies and formulation expertise to handle challenging fills, such as hygroscopic (moisture-absorbing) powders that can make hard capsules brittle (often managed with vegetarian capsules or specific fillers/packaging), or high-viscosity liquids that are difficult to fill into softgels.

Manufacturing facilities use automated high-speed filling machines with precise dosing mechanisms (e.g., dosators, tampers, pumps). In-process checks and statistical weight analysis are conducted throughout the production run to ensure that each capsule contains the correct, uniform amount of fill material within acceptable tolerances.

After the body is filled, automated capsule filling machines rejoin the cap to the body. Many modern machines apply a gentle locking mechanism during this process. For liquid-filled hard capsules, an additional step called "banding" or "sealing" is performed after filling and joining to create a tamper-evident, leak-proof seal around the seam.

Softgels are encapsulated and sealed simultaneously in a single process using rotary dies that apply heat and pressure to fuse the two shell ribbons together around the fill. Rigorous quality control checks, including visual inspection and physical testing, are performed to verify the integrity of this hermetic (airtight) seal and prevent leaks.

Many, but not all, capsule manufacturers have specialized equipment for filling hard capsules with non-aqueous liquids or semi-solids. This requires specific filling machinery and a post-filling sealing step (banding) to prevent leakage.

Manufacturers perform disintegration testing (measuring the time it takes for the capsule shell to break apart in a liquid medium) and dissolution testing (measuring how quickly the active ingredients are released and dissolve from the capsule) according to pharmacopeial standards relevant to the product and its intended release profile (standard, delayed, enteric).

Capsules undergo visual inspection (manual or automated) to check for physical defects such as inconsistencies in size, shape, color variations, foreign matter, damage (dents, cracks), and proper sealing/joining.

Yes, weight variation testing is a standard quality control measure. A sample of filled capsules from each batch is weighed to ensure that the fill weight is consistent across the batch and falls within acceptable regulatory tolerances.

Testing includes visual inspection for leaks or defects, and physical tests such as seam strength testing (measuring the force required to pull the seam apart) and often texture analysis to check shell firmness and elasticity, ensuring the shell is robust enough and the seal is intact.

Yes, MOQs are highly dependent on the capsule type (softgels often have higher MOQs than hard capsules), size (larger sizes might have lower unit counts per batch but still high MOQ by piece count), and the complexity of the fill or shell (e.g., custom colors, enteric coating, or challenging fills can influence MOQs). Custom formulations usually have higher MOQs than stock private label options.

Cost is influenced by the raw material cost of the shell (vegetarian shells are often more expensive than gelatin), the manufacturing complexity (softgels generally require more specialized equipment and process control than hard capsules), and the fill volume (larger capsules or denser fills mean fewer capsules needed per dose/bottle, impacting packaging costs).

Lead times vary based on the manufacturer's schedule, the complexity of the formula and capsule type, sourcing time for ingredients and packaging, and the current production load. They can range from a few weeks for standard private label hard capsules to several months for complex custom softgels or formulations requiring specialized testing or sourcing.

Common primary packaging options include plastic bottles (HDPE, PET), glass bottles, and blister packs (PVC/Aluminum). Some manufacturers also offer pouches or specialized unit-dose packaging.

Yes, manufacturers work with packaging suppliers to offer various child-resistant (CR) closure options for bottles and standard tamper-evident features like induction seals for bottles and the inherent sealing of blister packs and pouches.