Dietary Supplement Contract Manufacturer

Turning Your Dietary Supplement Ideas into Reality

As A Leading Dietary Supplement Contract Manufacturer Based In The China, We Specialize In The Production Of A Wide Range Of High-Quality Nutritional Supplements. Our Core Offerings Include The Contract Manufacturing Of Various Vitamins, Potent Herbal Extracts, Essential Minerals, And Beneficial Amino Acids, Providing Comprehensive Solutions For Brands Looking To Bring Effective And Reliable Health And Wellness Products To Market.

Our Dietary Supplement Contract Manufacturing Services

Formula Development & Customization

We offer professional dietary supplement formula design and optimization services based on your needs or existing formulas.

Raw Material Sourcing & Quality Control

We have a strict supply chain management system to ensure all raw materials undergo rigorous quality testing and meet high standards.

Dietary Supplement Contract Manufacturing

Outsourcing supplement production to specialized manufacturers, offering custom formulation, quality testing, regulatory compliance, and scalable production of capsules, gummies, and powders for efficient market entry.

Packaging & Labeling Design

We provide comprehensive packaging solutions, including various bottle types, materials, and label design services to help your products stand out.

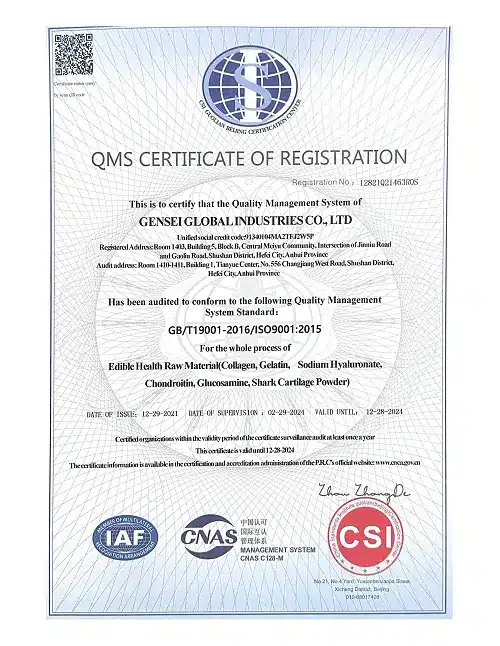

Quality Testing & Certification Support

We conduct thorough product quality testing and assist you in completing relevant certification applications to ensure your products meet regulatory requirements.

Warehousing & Logistics

We offer a secure warehousing environment and reliable logistics services to ensure your products are delivered on time.

Who We Are?

Gensei is your premier one-stop source for a wide range of high-quality dietary supplement ingredients, serving customers worldwide. We specialize in providing protein peptides, vitamins, amino acids, and herb-extracts. To ensure fast and efficient delivery, we maintain readily available stock in our warehouses located in the USA, Egypt, and Southeast Asia, saving you valuable procurement time.

Beyond being a leading amino acids supplier, mineral nutrients supplier, and vitamins factory for raw materials, Gensei also offers comprehensive OEM and ODM professional customization services. As your trusted Dietary Supplement Contract Manufacturer, we can guide you through every step, from selecting the finest ingredients to developing the perfect formula and designing attractive packaging. This makes us an ideal partner for brands focused on areas like sports nutrition and joint health.

Furthermore, to help you optimize production costs, we can also supply finished dietary supplement products manufactured in China. Whether you need specialty ingredients or a complete manufacturing solution, Gensei is dedicated to providing you with top-notch products and services to meet your specific needs in the dynamic health and wellness market.

Showcasing Innovation on the Global Stage

Gensei deeply understands the importance of building strong relationships with our clients. By attending global exhibitions, we engage in in-depth communication with customers from diverse cultural backgrounds, understand their specific requirements, and provide tailored solutions to help them succeed in the global market.