Our professional team will support you to go further!

Get a Quote. Ask a Question. We respond within 10 to 15 minutes during business hours.

gummy supplement manufacturer

As a leading gummy supplement manufacturer, Gensei sets itself apart with unparalleled expertise, innovative solutions, and a commitment to elevating your brand. Specializing in high-quality, chewable gummy supplements, Gensei offers fully customized formulations, flavors, shapes, and packaging to create delicious, consumer-friendly products that align with your brand’s vision. Our state-of-the-art, GMP-certified facilities ensure precision and safety, producing gummies with premium ingredients, including vegan, sugar-free, and organic options.

Gensei’s end-to-end services—from R&D to private labeling—streamline production, saving you time and costs while delivering market-ready gummies that stand out in the competitive nutraceutical market. By partnering with Gensei, your brand gains a trusted ally dedicated to quality, innovation, and consumer trust, driving growth and loyalty through tailored, high-efficacy supplements. Ready to transform your gummy supplement line? Contact Gensei today to bring your vision to life!

what is gummy supplement manufacturing?

Gummy Supplement Manufacturing is the process of producing chewable dietary supplements in gummy form, combining active ingredients like vitamins, minerals, botanicals, or other nutraceuticals with a gelatin or pectin base to create a flavorful, easy-to-consume product. This manufacturing caters to consumers seeking an alternative to pills or capsules, popular for wellness, beauty, and pediatric nutrition. Below is a concise overview of the process and key aspects, tailored to the context of manufacturers like Gensei:

- Formulation Development:

- Ingredients (e.g., vitamins, collagen, CBD) are blended with a gelling agent (gelatin for traditional gummies or pectin for vegan/vegetarian options) and sweeteners (e.g., cane sugar, stevia, or sugar-free alternatives).

- Formulations are customized for flavor, texture, and nutritional goals, ensuring stability and compliance with regulations like FDA or GMP standards.

- Ingredient Sourcing and Testing:

- High-quality raw materials are sourced from verified suppliers and tested for purity, potency, and safety to ensure no contaminants (e.g., heavy metals, microbes).

- Cooking and Mixing:

- Ingredients are heated and mixed to create a homogenous slurry, with precise control over temperature and viscosity to achieve the desired gummy texture.

- Molding:

- The slurry is poured into molds to form gummies in various shapes (e.g., bears, squares, custom designs) and sizes, tailored to client specifications.

- Starch or silicone molds are used for precision and consistency.

- Cooling and Setting:

- Gummies are cooled in controlled environments to solidify, ensuring a uniform, chewy texture without stickiness.

- Coating and Finishing:

- Gummies may be coated with sugar, citric acid, or oil to enhance flavor, prevent sticking, or improve shelf life.

- Visual inspection removes defective units (e.g., misshapen or uneven gummies).

- Quality Control:

- Products are tested for active ingredient potency, texture, and compliance with regulatory standards.

- Stability testing ensures gummies maintain quality throughout their shelf life (typically 12–24 months).

- Packaging:

- Gummies are packed into bottles, pouches, or blister packs with custom branding and labels, ensuring moisture resistance and consumer appeal.

- Tamper-evident seals and child-resistant packaging may be included.

Key Features:

- Customization: Options for flavors (e.g., fruit, citrus), colors, shapes, and formulations (e.g., vegan, organic, low-sugar) to align with brand identity.

- Consumer Appeal: Gummies are easy to consume, palatable, and popular with all age groups, especially children and those who dislike swallowing pills.

- Regulatory Compliance: Adherence to strict standards ensures safe, market-ready products.

- Scalability: Manufacturers like Gensei support small batches for startups or large-scale production for established brands.

Gensei’s Value: As a gummy supplement manufacturer, Gensei stands out by offering tailored solutions that elevate your brand. With expertise in innovative formulations, eco-friendly options (e.g., pectin-based gummies), and private labeling, Gensei ensures high-quality, consumer-focused products that drive market success.

If you’d like more details, insights into Gensei’s specific processes, or real-time data from X posts or web searches, let me know!

Features of working with gummy supplement manufacturerr:

Partnering with a gummy supplement manufacturer, such as Gensei, offers distinct advantages for businesses looking to develop and market high-quality, consumer-friendly dietary supplements in gummy form. Below are the key features of working with a reputable gummy supplement manufacturer, tailored to highlight the value Gensei brings to your brand:

- Customized Formulations:

- Manufacturers work closely with clients to create tailored gummy formulations, incorporating active ingredients like vitamins, minerals, botanicals, or specialty compounds (e.g., collagen, CBD) to meet specific health or market goals.

- Gensei’s expertise allows for unique blends, such as vegan, sugar-free, or organic gummies, ensuring your brand stands out with innovative, consumer-driven products.

- Flexible Product Design:

- Options for gummy shapes (e.g., bears, cubes, custom molds), sizes, colors, and flavors (e.g., fruit, citrus, or natural profiles) to align with your brand’s identity and target audience.

- Gensei offers advanced flavor-masking and texture optimization, enhancing palatability for kids, adults, or niche markets like beauty or wellness.

- Private Labeling and Branding:

- Comprehensive private label services enable you to market gummies under your own brand with custom logos, labels, and packaging (e.g., bottles, pouches, blisters).

- Gensei’s branding support ensures your gummies reflect your brand’s vision, with eye-catching designs that boost shelf appeal and consumer trust.

- High-Quality Production Standards:

- Adherence to Good Manufacturing Practices (GMP) and regulatory standards (e.g., FDA, Health Canada, ISO) ensures safe, consistent, and high-quality gummies.

- Gensei’s rigorous testing for potency, purity, and contaminants (e.g., heavy metals, microbes) guarantees reliable products that build consumer confidence.

- Vegan and Sustainable Options:

- Expertise in pectin-based (gelatin-free) gummies caters to vegan, vegetarian, and eco-conscious consumers, addressing dietary restrictions and sustainability trends.

- Gensei’s commitment to eco-friendly materials, like recyclable packaging or plant-based gelling agents, enhances your brand’s appeal to environmentally aware markets.

- Scalable Production Capacity:

- Flexible manufacturing supports small batches for startups or large-scale runs for established brands, ensuring scalability as your business grows.

- Gensei’s high-capacity facilities deliver consistent quality and timely production, meeting market demands without delays.

- End-to-End Support:

- From formulation and R&D to packaging and regulatory compliance, manufacturers provide full-service solutions, simplifying the process for clients.

- Gensei’s dedicated team guides your brand through every step, offering expertise in ingredient sourcing, market trends, and compliance to streamline your product launch.

- Cost Efficiency and Budget Control:

- Outsourcing to a manufacturer eliminates the need for in-house equipment, facilities, or specialized staff, reducing costs and risks.

- Gensei’s transparent pricing and efficient processes ensure your brand gets high-quality gummies within budget, maximizing ROI.

- Consumer-Centric Appeal:

- Gummies are palatable, easy to consume, and popular across age groups, making them ideal for kids, seniors, or those who dislike pills.

- Gensei’s focus on appealing textures, flavors, and clean-label ingredients (e.g., no artificial colors) enhances consumer satisfaction and loyalty for your brand.

- Innovation and Market Trends:

- Manufacturers stay ahead of trends, offering innovative options like functional gummies (e.g., sleep support, immunity boosters) or clean-label formulations.

- Gensei’s R&D capabilities help your brand capitalize on emerging markets, such as plant-based or low-sugar gummies, keeping you competitive.

- Fast Turnaround and Reliability:

- Efficient production timelines and robust supply chains ensure quick delivery, critical for meeting market deadlines or seasonal demands.

- Gensei’s reliable processes and proactive communication keep your brand on track, from concept to shelf.

Gensei’s Unique Value to Your Brand: Partnering with Gensei as your gummy supplement manufacturer elevates your brand through unparalleled customization, cutting-edge vegan and sustainable options, and a commitment to quality. Gensei’s expertise in creating market-ready, consumer-loved gummies ensures your brand achieves differentiation, trust, and growth in the competitive supplement industry.

gummy supplement style

| Style Aspect | Specific Style / Option | Description / Characteristics |

|---|---|---|

| Gelling Agent (Base) | Gelatin-based | Classic chewy, elastic, and bouncy texture; melts well in the mouth for good flavor release. |

| Pectin-based | Plant-based (vegan/vegetarian); softer, shorter bite that breaks down easily; excellent flavor release. | |

| Starch-based (e.g., Tapioca) | Can result in a longer chew, sometimes slightly stickier; often used for specific functional gummies. | |

| Blended Hydrocolloids | Combinations of gelling agents (e.g., pectin + agar) to achieve unique, customized textures. | |

| Texture Profile | Soft & Chewy | Most common and desired; easy to chew and pleasant mouthfeel. |

| Firm & Elastic | More resistant to chew, longer lasting in the mouth. | |

| Tender / Short Bite | Breaks down easily, less "springy." | |

| "Melt-in-Mouth" | Designed to dissolve quickly in the mouth with minimal chewing. | |

| Sweetener Profile | Sugar-Containing | Uses traditional sugars (e.g., sucrose, corn syrup) for classic sweetness and texture. |

| Sugar-Free | Uses sugar alcohols (erythritol, xylitol) or zero-calorie natural sweeteners (stevia, monk fruit); often firmer. | |

| Low-Sugar | Reduced sugar content compared to traditional gummies. | |

| Flavor & Aroma | Classic Fruity | Common and widely accepted flavors like strawberry, orange, lemon, mixed berry. |

| Tropical / Exotic | Flavors like mango, pineapple, passion fruit, or unique fruit blends. | |

| Sour Profiles | Achieved with an acid coating for a tangy, mouth-puckering experience. | |

| Herbal / Functional | Flavors designed to complement specific benefits (e.g., ginger-lemon for digestion, mint for freshness). | |

| Appearance & Aesthetics | Shape (Standard) | Common shapes include gummy bears, fruit shapes (berries, slices), domes, worms, or squares. |

| Shape (Custom/Novelty) | Unique, branded shapes (e.g., stars, animals, specific logos) for differentiation. | |

| Color | Can be vibrant, natural (from fruit/veg concentrates), muted, or multi-colored/layered. | |

| Transparency | Clear/translucent vs. opaque appearance. | |

| Coatings | Sugar-Coated | Provides a sweet, slightly crunchy exterior and prevents sticking. |

| Sour-Coated | Uses an acid blend for a tangy flavor experience and anti-stick properties. | |

| Oil / Wax-Coated | Applied with edible oils or waxes (e.g., carnauba wax) for gloss and to prevent sticking. | |

| Powder-Coated | Can be used for anti-stick or to apply additional actives/flavors post-molding. |

How Does gummy supplement manufacturing Work?

Ingredient Preparation & Mixing:

- Base Ingredients: The process begins with carefully weighing and preparing the core ingredients for the gummy base, which typically include a gelling agent (such as gelatin, pectin, or a blend of hydrocolloids), sweeteners (sugar, corn syrup, or sugar alternatives like maltitol, erythritol, stevia), and water.

- Nutrient & Flavor Blending: Active ingredients (vitamins, minerals, botanicals, etc.), flavors, colors, and often acids (like citric or malic acid) are then precisely measured and thoroughly blended into the liquid gummy base. This step requires careful consideration of ingredient compatibility and stability, especially concerning heat and pH.

Cooking & Slurry Formation:

- The mixed ingredients are transferred to large kettles or continuous cooking systems. They are heated to specific temperatures and blended to achieve a “slurry” or “syrup” consistency. The cooking process is critical for dissolving all ingredients, activating the gelling agent, and reaching the correct Brix (sugar concentration) and viscosity.

- Maintaining a homogenous mixture is crucial to ensure consistent dosage and quality in every gummy.

Depositing & Molding:

- The hot gummy slurry is transferred from the cooking/storage tank to a depositor machine.

- Starch Molding (Traditional): Impressions of the gummy shape are made in trays filled with corn starch. The hot gummy mixture is deposited into these starch molds. The starch helps to absorb moisture from the gummy and prevents sticking as it cools and sets.

- Starchless Molding (Modern): This method uses reusable silicone, Teflon-coated metal, or plastic molds. The depositor precisely fills these molds, which often feature chilling and oil-spraying mechanisms to facilitate release. This method is often preferred for functional gummies due to reduced risk of cross-contamination from starch.

Cooling & Demolding:

- Once filled, the molds (whether starch trays or reusable molds) are transported through a cooling tunnel or chilling system. Rapid and controlled cooling is essential for the gummies to set their shape and develop the desired texture.

- After sufficient cooling, the gummies are demolded (removed from their molds). In automated systems, this often involves inverting trays or using robotic arms to extract the gummies.

Drying&Curing:

- This is a critical step for gummy stability and texture. The demolded gummies are typically transferred to drying rooms or tunnels with controlled temperature and humidity.

- Gummies are often left to dry for an extended period (ranging from 24 hours to several days, depending on the formulation and desired texture). This process reduces the moisture content to a specific water activity level, which prevents microbial growth, stickiness, and helps achieve the final desired chewiness and shelf life.

Coating & Polishing:

- Once dried, gummies often go through a coating or polishing stage in rotating drums:

- Sugar Coating: A layer of sugar is applied to prevent sticking and add a textural element.

- Sour Coating: A blend of acids (like citric or malic acid) is applied for a tangy flavor.

- Oil/Wax Coating: Edible oils or waxes (e.g., carnauba wax) are used to prevent sticking and provide a glossy finish.

- Some gummies are left uncoated for a softer, less textured exterior.

- Once dried, gummies often go through a coating or polishing stage in rotating drums:

Quality Control & Packaging:

- Throughout the entire process, rigorous quality control checks are performed, including testing for active ingredient potency, purity (heavy metals, microbial contaminants), consistency in size and weight, texture, pH, and overall appearance.

- Finally, the finished gummies are counted and filled into various packaging formats such as bottles, pouches, or blister packs, ready for distribution.

Choose the Right Package for Your gummy

Bottles (Plastic or Glass)

- Description: The most common and versatile option. Gummies are counted and filled into bottles, usually with a desiccant packet to control moisture. Plastic types like HDPE (high-density polyethylene), PET (polyethylene terephthalate), and PP (polypropylene) are widely used, as is glass.

- Pros:

- Excellent Protection: Provides strong physical protection against crushing and external contaminants.

- Moisture & Oxygen Barrier: Good barrier properties, especially with HDPE, dark glass, or appropriate liners, which are crucial for gummy stability.

- Child-Resistant Closures (CRCs): Readily available for safety, particularly important for appealing, candy-like supplements.

- Branding Space: Offers ample surface area for labels and branding, allowing for attractive designs.

- Consumer Familiarity: A widely accepted and convenient format for multi-dose products.

- Cons:

- Bulk & Weight: Can be heavier and bulkier than other options, increasing shipping costs.

- Stickiness Challenges: Without proper anti-stick coatings on the gummies or bottle liners, gummies can clump together, especially at the top or bottom of the bottle.

- Description: The most common and versatile option. Gummies are counted and filled into bottles, usually with a desiccant packet to control moisture. Plastic types like HDPE (high-density polyethylene), PET (polyethylene terephthalate), and PP (polypropylene) are widely used, as is glass.

Pouches / Bags (Flexible Packaging)

- Description: Increasingly popular, especially for larger quantities, refills, or single-serving packs. These are typically stand-up pouches with re-sealable zippers, made from multi-layer barrier films.

- Pros:

- Lightweight & Portable: Excellent for on-the-go consumers and reduces shipping costs.

- Space Efficient: Takes up less space than rigid bottles, both in storage and transport.

- Good Barrier Properties: Can offer excellent protection against moisture and oxygen with the right film laminates.

- Ample Branding Space: Provides a large canvas for graphics and product information.

- Sustainability Potential: Some pouches are becoming more recyclable, though challenges remain.

- Lightweight & Portable: Excellent for on-the-go consumers and reduces shipping costs.

- Cons:

- Less Physical Protection: Gummies are more susceptible to crushing or deformation than in bottles.

- Stickiness Potential: Can be challenging if gummies are very sticky, leading to clumping within the bag.

- Dispensing: Less precise dispensing for multi-dose products compared to bottles (though re-sealable zippers help with freshness).

Blister Packs

- Description: Individual gummies are sealed in separate cavities formed from plastic (e.g., PVC, PVDC for barrier) with a foil backing. Less common for large quantities of gummies but excellent for unit-dose.

- Pros:

- Superior Individual Protection: Each gummy is protected from moisture, oxygen, and contamination until consumed.

- Portion Control & Hygiene: Ensures precise dosing and maintains the freshness of each individual gummy.

- Tamper Evidence: Offers clear tamper-evident features.

- Travel-Friendly: Compact and easy for consumers to carry a few doses.

- Cons:

- Higher Cost per Gummy: Generally more expensive per unit than bottles or pouches for high volumes.

- Limited Branding Space: Requires an outer carton for extensive branding and product information.

- Accessibility: Can be difficult for some individuals (e.g., elderly, those with dexterity issues) to open.

What Makes Us Unique As A gummy supplement manufacturer?

We design your specific gummy with your whole business in mind. With Gensei, you’ll get a trusted supplement manufacturing team who knows the industry and how to deliver the best product for your brand.

- Mastery of Gummy Science & Sensory Appeal: We go beyond basic production, specializing in the intricate science of gummy texture, flavor masking, and mouthfeel. Our R&D team excels at creating the perfect chew, optimal flavor release, and non-sticky finish, ensuring a superior consumer experience.

- Versatile Gelling Agent Expertise: Unlike manufacturers limited to one base, we have proven proficiency across various gelling agents – gelatin, pectin, and even hybrid blends. This allows us to craft gummies that meet specific dietary needs (vegan, vegetarian) and achieve diverse texture profiles.

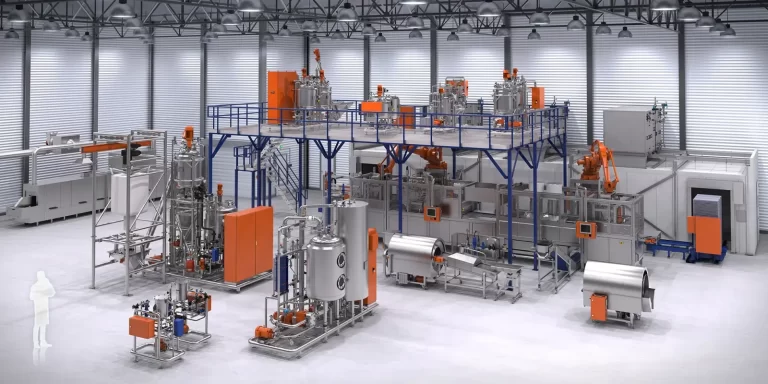

- Advanced Gummy Production Technology: We utilize state-of-the-art, high-capacity cooking, depositing, and drying lines specifically engineered for gummies. This ensures precise dosing, consistent product formation, and efficient scalability for your brand's growth.

- Innovative Flavor & Sweetener Solutions: Our flavor specialists are adept at developing delicious, natural flavor profiles and navigating complex sweetener systems (sugar-free, low-sugar, natural alternatives) to create gummies that taste great without compromise.

- Rigorous Gummy-Specific Quality Control: Our quality assurance extends beyond standard potency testing. We implement specialized checks for gummy stability, texture consistency, water activity, and anti-stick properties to guarantee your gummies maintain their integrity, freshness, and appeal throughout their shelf life.

- Customization & Creativity at Scale: From intricate custom shapes and vibrant natural colors to specialized coatings (sour, sugar, oil/wax), we offer extensive customization options. This allows your brand to stand out visually and aesthetically in a competitive market.

- Comprehensive Turnkey Solutions for Gummies: We offer an end-to-end service specifically tailored for gummies, from initial concept and custom formulation, through ingredient sourcing, specialized manufacturing, stringent QC, and optimal packaging solutions designed to protect gummy integrity.

- Problem-Solving & Stability Focus: We anticipate and overcome common gummy challenges like active ingredient degradation, moisture migration, and stickiness, ensuring your finished product is stable, compliant, and performs exactly as intended.

Gummy Supplement Manufacturing Certification

We at Gummy Supplement manufacture to the following standards and requirements.

Frequently Asked Questions About capsule supplement manufacturing

Gummies are versatile! Common actives include vitamins (A, C, D, E, B-complex), minerals (some can be challenging due to taste/reactivity), Omega-3s, collagen, biotin, melatonin, probiotics (often microencapsulated for stability), and various botanical extracts.

The main gelling agents are gelatin (animal-derived, providing a classic chewy texture) and pectin (plant-based, offering a softer, "shorter" bite, popular for vegan/vegetarian products). Other options like starch or blends of hydrocolloids can also be used.

Yes, absolutely. Many manufacturers offer sugar-free options using sugar alcohols (like erythritol, xylitol, maltitol) or natural zero-calorie sweeteners (stevia, monk fruit). Low-sugar formulations are also a growing trend.

Manufacturers employ specialized flavor masking techniques, using strong natural or artificial flavors, and sometimes acidic coatings, to effectively cover up undesirable tastes or odors from ingredients like certain vitamins or botanicals.

Highly heat-sensitive ingredients, those with very low pH (which can degrade certain gelling agents), or ingredients requiring very high dosages (making the gummy impractically large) can be challenging. Some minerals may also interact with the gummy matrix, affecting taste or stability.

The process generally involves: 1) Careful Ingredient Preparation & Mixing, 2) Cooking the gummy slurry, 3) Precise Depositing into molds (either traditional starch or modern starchless molds), 4) Controlled Cooling, 5) Demolding, 6) Critical Drying/Curing (to achieve final texture and stability), and 7) Coating & Polishing, followed by final packaging.

Rigorous quality control (QC) is performed at every stage. This includes precise weighing of raw materials, automated depositing for accurate fill volume, in-process checks for Brix (sugar concentration), pH, and viscosity, and comprehensive finished product testing for active ingredient potency, weight uniformity, texture, water activity, and microbial purity.

Reputable gummy manufacturers adhere to cGMP (Current Good Manufacturing Practices) regulations (often FDA-registered). Many also pursue third-party certifications like NSF, USDA Organic, Kosher, Halal, or allergen-specific certifications to meet diverse market demands and assure quality.

This is a common challenge for gummies. Manufacturers employ several strategies: precise moisture control during the drying/curing phase, applying anti-stick coatings (like carnauba wax, sugar, or sour blends), and selecting appropriate packaging materials and desiccants to absorb excess moisture.

Yes, customization is a significant advantage of gummies. Manufacturers can produce a wide array of custom shapes using specialized molds, offer extensive color options (from natural fruit/vegetable concentrates to artificial dyes), and develop unique flavor profiles.

"Chewable" is inherent to gummies. While less common than for softgels, some manufacturers can achieve modified-release properties (e.g., to reduce "fish burps") or even a form of enteric coating through specialized shell formulations or post-coating processes.

The timeline can vary based on formulation complexity, ingredient sourcing, R&D testing, and current production schedules. Generally, from initial concept to finished product delivery, it can range from 4-8 months or more.

MOQs for gummies are typically higher than for other supplement forms due to the specialized equipment and complex process. They can range from 100,000 to 500,000 units or even higher, depending on the manufacturer, gummy type, and level of customization.

Common packaging includes plastic or glass bottles (often with child-resistant caps), flexible stand-up pouches, and in some specialized cases, blister packs for individual dosing.

Stability is paramount. Manufacturers conduct rigorous stability testing under various conditions (temperature, humidity) to determine and validate the product's shelf life. This is supported by careful formulation, precise moisture control during drying, and the selection of appropriate barrier packaging.